Nitrogen management on wheat: Production, environmental and quality implications

Principal Investigator: Peter Johnson and Jayne Bock

Research Institution: Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) / University of Guelph

Timeline: April 2014 – March 2017

Objectives:

- Evaluate nitrogen (N) response curves for wheat (soft red winter, SRW; hard red winter, HRW; hard red spring, HRS) both with and without fungicides.

- Develop a wheat N calculator that includes fungicide use as a parameter.

- Evaluate N management impacts on wheat quality.

- Determine if protein quantity in Ontario HRW is a good indicator of functionality.

Impacts:

- The development of a wheat N calculator may allow for reduced N use and increase grower profitability, while reducing potential environmental impact.

- The determination of flour functionality will allow for the processing industry to find ways to better utilize the quality of wheat grown in Ontario and may open new markets.

- The producers and the processing industry may see improvements in terms of growing high yields of wheat that offer the best quality to the wheat industry.

Scientific Summary:

Wheat is a major crop in Ontario, with a combined winter and spring acreage of approximately 1 million acres grown annually. Unfortunately, keeping wheat in the Ontario rotation is a constant struggle because wheat yield increases and profitability lag far behind those for corn and soybeans. Wheat is extremely valuable in the rotation under Ontario conditions, adding up to 8 bu/ac of corn yield, and 5 bu/ac of soybean yield (Ontario Rotation Trials). Including wheat in the rotation greatly improves soil health and organic matter, making soils more resilient when climatic extremes are encountered. Finding ways to keep wheat profitable and in the rotation is critical. Recent quality issues have also had acreage impacts. Poor quality in 2011 and 2012 resulted in premiums dropping for HRW, which in turn have resulted in significant drops in the amount grown (7.5% of wheat acreage in 2014 from 21% in 2006). Wheat yields, profitability, and quality must all be addressed to maintain wheat acres in the province. The development of a nitrogen calculator for wheat would greatly improve environmental impacts, wheat quality, and grower profitability.

This project evaluated N response curves for wheat (soft red winter, hard red winter, and hard red spring), with and without fungicides, and assessed these management inputs through to the quality of the flour in the milling industry. These data, along with previous N data from Ontario, were used to develop an Ontario N calculator for wheat. In addition, this project evaluated protected N sources and Plant Growth Regulator (PGR) technology to determine the impact on yield, protein, maturity, lodging and economics. The samples from these trials were evaluated for milling and baking quality as field management has a significant impact on wheat flour functionality. Samples were evaluated for quality parameters that have been identified by industry as problematic in the current wheat supply. Protein quality was also assessed in hard wheat to help the industry better understand implications of field management, and whether accepted standards such as protein quantity were the right measure to use for actual flour functionality and protein quality.

Conclusions:

The significance of this study shows that, while grower nitrogen and fungicide management can impact baking quality, those impacts are inconsistent and that the impact of protein levels is the predominant player in end use quality. Normal grower practices, particularly having N applications at or near MER-N, definitely also tended to have the highest baking quality for many parameters. Growers can feel confident that normal management practices will continue to deliver a high-quality product for end users, and that management changes are not required for quality purposes.

This study also shows that current N recommendations (Agronomy Guide) may not be sufficient as growers continue to utilize fungicides, due to the synergistic relationship of additional nitrogen and fungicide use. Growers using fungicides in both winter and spring wheats should continue to test higher nitrogen rates, to determine their own optimum nitrogen applications. Growers in the Ottawa valley (Area 3) should increase N rates on spring wheat cautiously, as data indicates less response in that region than in other regions of the province.

Next Steps:

Nitrogen response data should continue to be generated, as genetic yield potential and other management opportunities evolve. Wheat value and fertilizer cost will continue to be factors that need to be considered when making nitrogen decisions.

Detailed Results:

- The flour yield, protein, and ash contents of wheat variety (Len site) at different N rates (0, 60, 90, 120, 150 and 180 N) with or without fungicide harvested in 2015 and 2016, respectively, is shown in Table 1. There were no significant differences in flour yield and ash content for this site under different N rates with or without fungicide for all the samples (P > 0.05). The N rate had remarkable effects on the protein of the samples with fungicide treatment harvested in 2015 and without fungicide harvested in 2016 (P < 0.05). A treatment of 150 N lb/ac resulted in the highest protein content, followed by 180 and 120 N lb/ac.

Table 1. Flour yield, protein and ash content of Len with different N rate treatments

| N rate Treatment (lb/ac) | Flour yield (%) | Protein (%) | Ash (%) | ||||

| 2015 | 2016 | 2015 | 2016 | 2015 | 2016 | ||

| 0 | No Fung | 60.6 ± 1.8 | 63.9 | 9.48 ± 0.24 | 8.24 ± 0.1AB | 0.48 ± 0.03 | 0.42 ± 0 |

| Fung | 63.4 ± 1.9 | 63.6 | 9.14 ± 0.93ab | 8.32 ± 0.07 | 0.42 ± 0.04 | 0.41 ± 0.04 | |

| 60 | No Fung | 65.1 ± 0.3 | 65.3 | 9.56 ± 0.41* | 6.97 ± 0.12B | 0.43 ± 0.03 | 0.43 ± 0.02 |

| Fung | 63.7 ± 3.2 | 66.4 | 7.71 ± 1.1b | 7.36 ± 0 | 0.43 ± 0.05 | 0.35 ± 0.03 | |

| 90 | No Fung | 65.2 ± 3.5 | 64.8 | 9.33 ± 0.02* | 6.74 ± 0.05B* | 0.45 ± 0.02 | 0.44 ± 0.01* |

| Fung | 61.2 ± 0.3 | 65.3 ± 1.9 | 7.85 ± 0.26ab | 8.46 ± 0.19 | 0.44 ± 0.03 | 0.38 ± 0.02 | |

| 120 | No Fung | 68.7 ± 3.6 | 65.7 ± 0.3 | 9.65 ± 1.25 | 6.87 ± 0.66B | 0.44 ± 0.07 | 0.41 ± 0.03 |

| Fung | 63.8 ± 3.0 | 64.7 ± 2.1 | 9.34 ± 0.01a | 7.49 ± 0.55 | 0.42 ± 0.08 | 0.39 ± 0.04 | |

| 150 | No Fung | 66.3 ± 2.3 | 65.7 ± 1.6 | 9.66 ± 1.21 | 8.6 ± 0.85A | 0.48 ± 0.02 | 0.37 ± 0.02 |

| Fung | 62.8 ± 2.2 | 65.8 ± 0.1 | 8.21 ± 0.6ab | 8.55 ± 0.79 | 0.42 ± 0.06 | 0.42 ± 0.03 | |

| 180 | No Fung | 63.5 ± 4.5 | 63.2 ± 0.5 | 9.36 ± 0.39* | 7.64 ± 0.09AB | 0.49 ± 0.03 | 0.38 ± 0.05 |

| Fung | 63.2 ± 1.8 | 66.8 ± 1.1 | 7.74 ± 0.35b | 7.99 ± 0.55 | 0.46 ± 0.02 | 0.36 ± 0.03 | |

Data are mean ± SD, each value is a mean of 4 replicates.

Values within a same column followed by different capital letters for no fungicide treatments or followed by different

small letters for fungicide treatments are significantly different (P < 0.05), respectively, as determined by Tukey’s HSD

test following ANOVA. * indicates significant differences at P < 0.05 between with and without fungicide treatment.

- Table 2 shows the water absorption behavior, dough development time, stability, and tolerance index of flours for Len site treated under different N rates with or without fungicides harvested in 2015 and 2016, respectively. The N rate had no significant effects on the water absorption, development time, stability, tolerance index, time to breakdown and FQN for Len site harvested in 2015 without fungicide (P > 0.05), but it had remarkable effects on the water absorption and stability of the samples with fungicide treatment. Unexpectedly a N rate of 180 lb/ac treatment with fungicide had the lowest water absorption (P < 0.05). For the wheat harvested in 2016, the N rate had no significant effect on the water absorption, dough development time, stability, time to breakdown and Farinograph quality number of the samples treated with fungicide (P > 0.05), but it had significant effects on the water absorption, development time and tolerance index (P < 0.05) of the samples without fungicide. The N rate of 150 and 180 lb/ac treatment resulted in a higher water absorption and development time, but unexpectedly the treatment of 0 N lb/ac had the highest water absorption and development time (P < 0.05).

Table 2. Farinograph parameters of Len with different N rate treatments

| N rate (lb/ac) | Treatment | Water absorption (%) | Development time (min) | Stability (min) | Tolerance Index (FU) | ||||

| 2015 | 2016 | 2015 | 2016 | 2015 | 2016 | 2015 | 2016 | ||

| 0 | No Fung | 57.6 ± 1.3 | 57.8 ± 0.1A | 3.9 ± 1.5 | 1.6 ± 0.1A | 6.3 ± 0.6 | 1.6 ± 0.5 | 47.5 ± 17.2 | 47 ± 2.8AB |

| Fung | 57.9 ± 1.1 | 58.3 ± 0.3 | 3.7 ± 2.4 | 1.7 ± 0.3 | 4 ± 1.9ab | 2 ± 0.5 | 53 ± 5.4 | 49.5 ± 2.1abc | |

| 60 | No Fung | 59.1 ± 0.3 | 56.2 ± 0.3C | 3 ± 1.3 | 1.2 ± 0C | 6.2 ± 1.1 | 1.1 ± 0.1 | 31.5 ± 1.9 | 81.5 ± 4.9A |

| Fung | 57.9 ± 2.1 | 57.5 ± 0.4 | 1.6 ± 0.1 | 1.4 ± 0 | 1.8 ± 0.2b | 1.1 ± 0.1 | 43.5 ± 15 | 73.5 ± 3.5a | |

| 90 | No Fung | 58.5 ± 0.2 | 56.4 ± 0.4BC | 1.7 ± 0 | 1.4 ± 0ABC | 5.4 ± 0.3 | 1.1 ± 0.2* | 29.5 ± 3.5* | 74.5 ± 7.8A* |

| Fung | 58.6 ± 0.3 | 57.3± 0.2 | 4 ± 1.8 | 1.6 ± 0.1 | 4.7 ± 1.9ab | 5.8 ± 1.0 | 52.2 ± 9.3 | 28.8 ± 2.5c | |

| 120 | No Fung | 57.9 ± 0.4 | 56.5 ± 0.1BC | 3.7 ± 1.4 | 1.3 ± 0.1BC | 6.1 ± 0.8 | 1.2 ± 0.2 | 33.5 ± 10.1 | 70.3 ± 2.5AB |

| Fung | 58.5 ± 0.2 | 57.1 ± 0.4 | 1.8 ± 0.1 | 1.5 ± 0 | 4.2 ± 0.4ab | 1.2 ± 0.1 | 44 ± 0 | 65.3 ± 7.4ab | |

| 150 | No Fung | 57.3 ± 0.5 | 57.5 ± 0.1AB | 4.5 ± 0.2 | 1.6 ± 0.1AB | 5.9 ± 1.1 | 5.7 ± 0.6 | 36.3 ± 8.5 | 37.0 ± 6.4B |

| Fung | 58.1 ± 0.4 | 57.9 ± 0.2 | 3.6 ± 2 | 1.7 ± 0.1 | 4.5 ± 2.1ab | 4.9 ± 1.1 | 39.8 ± 5.3 | 38.5 ± 7.8bc | |

| 180 | No Fung | 59.1 ± 1.5* | 57.4 ± 0.1AB | 4.3 ± 1.7 | 1.4 ± 0.1ABC | 6.8 ± 1.8 | 1.2 ± 0.1 | 44 ± 9 | 59.8 ± 3.2AB |

| Fung | 55.9 ± 0.7 | 57.8 ± 0.3 | 3.2 ± 1.8 | 1.4 ± 0.1 | 6.1 ± 1.1a | 1.9 ± 0.1 | 33.8 ± 6.8 | 55.8 ± 3.2abc | |

Data are mean ± SD, each value is a mean of 4 replicates.

Values within a same column followed by different capital letters for no fungicide treatments or followed by different

small letters for fungicide treatments are significantly different (P < 0.05), respectively, as determined by Tukey’s HSD

test following ANOVA. * indicates significant differences at P < 0.05 between with and without fungicide treatment.

- Table 3 presents the gluten aggregation peak time, peak torque, and bread loaf volume of Len site samples under different N rates with or without fungicide harvested in 2015 and 2016, respectively. For the wheat harvested in 2015, the N rates had significant effects on the peak torque and bread loaf volume of the samples with or without fungicide (P < 0.05), but it had no remarkable effects on the peak time (P > 0.05). A treatment of 150 N lb/ac had the highest loaf volume for the samples with or without fungicide treatment. For the samples harvested in 2016, the N rates had significant effects on the peak time and bread loaf volume of the samples with or without fungicide treatment (P < 0.05), but it had no remarkable effects on the peak torque of those with fungicide (P > 0.05). Treatments of 150 and 180 N lb/ac had lower peak times and higher peak torques. Unexpectedly the highest peak torque was observed in 0 lb/ac without fungicide. The treatment of 150 N lb/ac had the highest loaf volume for the samples with or without fungicide treatment (Table 3).

Table 3. Gluten aggregating characteristics and baking performance of Len with different N rate treatments

| N rate Treatment (lb/ac) | Peak time (min) | Peak torque (BE) | Bread volume (ml) | ||||

| 2015 | 2016 | 2015 | 2016 | 2015 | 2016 | ||

| 0 | No Fung | 1.78 ± 0.12 | 2.8 ± 0.05B* | 37.31 ± 0.67AB* | 35.72 ± 0.23A | 531 ± 5.7B | 556.5 ± 7.8AB |

| Fung | 2.93 ± 0.94 | 2.54 ± 0.03b | 34.82 ± 0.5bc | 36.09 ± 0.26 | 520 ± 14.1a | 555 ± 21.2ab | |

| 60 | No Fung | 1.68 ± 0.13* | 3.7 ± 0.07A* | 37.88 ± 0.87AB | 30.95 ± 0.6AB | 531 ± 14.1B | 504.5 ± 0.7B |

| Fung | 2.11 ± 0.22 | 3.32 ± 0.11a | 36.37 ± 0.74ab | 32.89 ± 0.89 | 501 ± 1.4b | 520 ± 14.1ab | |

| 90 | No Fung | 1.69 ± 0.05 | 3.68 ± 0.16A* | 36.1 ± 0.12B | 29.19 ± 0.18B* | 583 ± 7.1AB | 491 ± 1.4B |

| Fung | 2.06 ± 0.24 | 2.45 ± 0.01b | 36.13 ± 1.06ab | 36.24 ± 0.46 | 550.5 ± 24ab | 548.3 ± 31.9ab | |

| 120 | No Fung | 1.8 ± 0.36 | 3.35 ± 0.04AB* | 37.27 ± 1.14AB | 29.70 ± 0.06B | 541 ± 12.7B | 488 ± 32.3B |

| Fung | 2 ± 0.09 | 3.08 ± 0.01a | 37.03 ± 0.11a | 32.29 ± 0.08 | 564 ± 8.5a | 511.5 ± 24.2ab | |

| 150 | No Fung | 1.58 ± 0.12* | 2.81 ± 0.16B* | 38.57 ± 0.76A* | 35.33 ± 0.18A | 592.5 ± 10.6A | 581.3 ± 37.5A |

| Fung | 3.11 ± 1.02 | 2.37 ± 0.03b | 33.88 ± 0.78c | 36.30 ± 0.10 | 574 ± 1a | 566.8 ± 28.7a | |

| 180 | No Fung | 1.91 ± 0.11 | 3.01 ± 0.03B* | 37.46 ± 0.86AB | 33.88 ± 0.05AB | 596.5 ± 11.5A | 527.8 ± 8.4AB* |

| Fung | 1.92 ± 0.24 | 2.56 ± 0.05b | 36.23 ± 1.38ab | 36.04 ± 0.79 | 559.5 ± 12ab | 494.5 ± 24.6b | |

Data are mean ± SD, each value is a mean of 4 replicates.

Values within a same column followed by different capital letters for no fungicide treatments or followed by different

small letters for fungicide treatments are significantly different (P < 0.05), respectively, as determined by Tukey’s HSD

test following ANOVA. * indicates significant differences at P < 0.05 between with and without fungicide treatment.

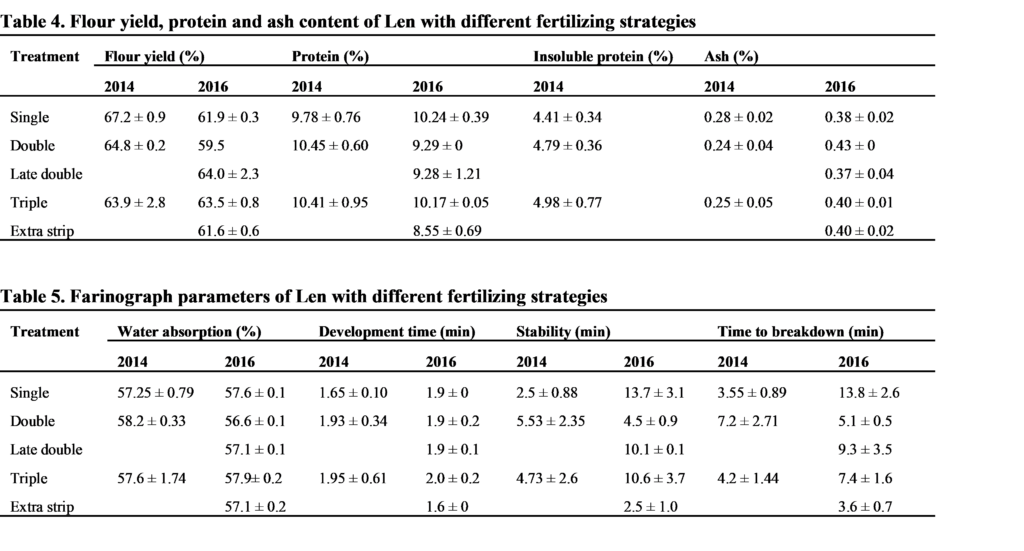

- Tables 4-6 show the flour yield, protein, ash, water absorption behavior, development time, stability, gluten aggregation kinetics, and baking performance of wheat grown with different N fertilizing strategies (single, double, late double, triple, and extra strip). There were no significant differences in the protein, ash, Farinograph characteristics, and Glutopeak torque of the flour from wheat (P > 0.05), but the GlutoPeak times were significantly different (P < 0.05). The single 150 N treatment had the longest peak time, and triple treatments resulted in the shortest time (P < 0.05). The fertilizing strategy had significant effects on the bread loaf volume of the samples harvested in 2016 (P < 0.05). The single treatment had the greatest loaf volume, followed by triple and double treatments.

Table 6. Gluten aggregating characteristics and baking performance of Len with different fertilizing strategies

| Treatment | Peak time (min) | Peak torque (BE) | Bread volume (ml) | ||||

| 2014 | 2016 | 2014 | 2016 | 2014 | 2016 | ||

| Single | 3.62 ± 0.31A | 2.72 ± 0.16 | 29.22 ± 2.59 | 37.74 ± 0.08 | 539.0 ± 10.9 | 609.5 ± 12.8A | |

| Double | 3.29 ± 0.10AB | 2.88 ± 0.11 | 31.45 ± 1.8 | 36.97 ± 0.65 | 546.5 ± 11.6 | 520 ± 0B | |

| Late double | 3.56 ± 0.09 | 34.37± 0.26 | 570.5 ± 40AB | ||||

| Triple | 3.09 ± 0.31B | 3.60 ± 0.06 31.46 ± 4.10 | 36.40± 0.23 | 548.3 ± 8.2 | 602.5 ± 18.6A | ||

| Extra strip | 2.82 ± 0.10 | 35.79 ± 0.21 | 530 ± 18.3B | ||||

Data are mean ± SD, each value is a mean of 4 replicates.

Values within a same column followed by different capital letters are significantly different (P < 0.05) as determined by Tukey’s HSD test following ANOVA.

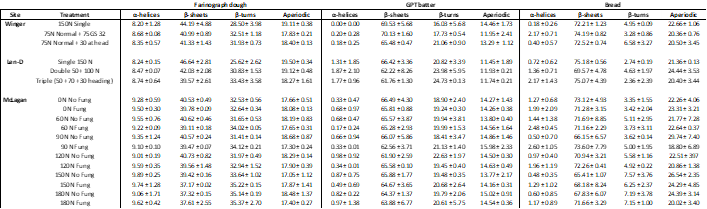

- Table 7 shows the effects of split nitrogen and fungicide treatment on the protein secondary structure in dough, batter, and bread. The results were relatively consistent across treatments for a given location. It appears that split nitrogen treatments and fungicide application do not significantly impact protein structure. This is a positive finding because it implies no fundamental change in end-use quality and functionality due to agronomic management.

Table 7. Effect of split nitrogen and fungicide treatment on winter wheat protein secondary structure

- For flour characteristics of samples with different N fertilizing strategies, there were no significant differences in the protein, insoluble protein and ash contents, development time, stability, time to breakdown, and FQN with different N fertilizing strategies (P > 0.05). The treatment of 75 N Normal + 75 GS 32 and 75 N Normal + 30 N at heading resulted in greater peak torques and water absorptions than those of 150 N single (P < 0.05). The tolerance index was higher for Winger treated by 150 N single and 75 N Normal + 75 GS 32 than the treatment of 75 N Normal + 30 N at head (P < 0.05).

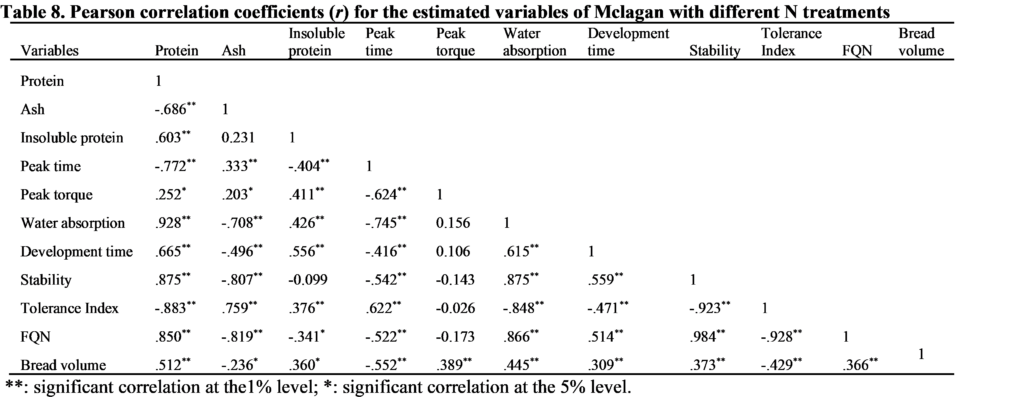

- The correlation analysis in Tables 8 and 9 show strong correlations (P ≤ 0.01) for bread volume with protein content, insoluble protein content, GlutoPeak torque, and Farinograph water absorption. Any significant changes in these quality parameters will be more likely to reflect concurrent changes in bread quality. Additional significant correlations exist among the other quality parameters although their relationship with bread quality is more complex.

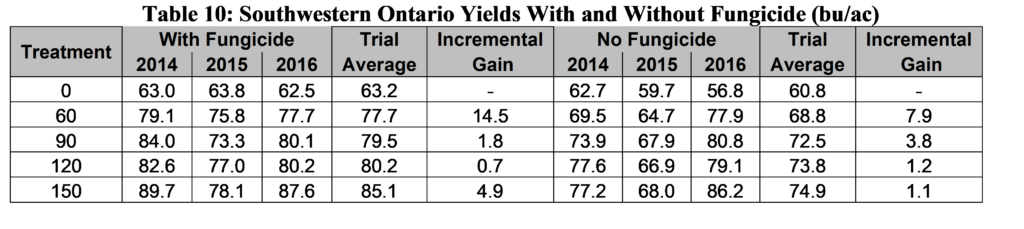

- A total of 10 spring wheat field trials containing N application rates of 0, 60, 90, 120, and 150 N, both with and without fungicide, were conducted in southwestern Ontario between 2014 and 2016. Small plot, 4 replicate trials were conducted at Winchester and New Liskeard. Four field plots were also conducted in the Winchester area over the duration of this project. Data collected from these sites included yield, moisture, test weight, 1000 kernel weights, protein, disease ratings and lodging. Fusarium damaged kernel (FDK) counts were completed on sites with high Fusarium levels.

- Using urea at $557/tonne ($0.55/lb of actual N) and hard red spring wheat at $5.50/bushel (current value at completion of project), 3 bushels of wheat are required to cover the cost of 30lbs of N ($0.55/lb*30lbs= $16.50/$5.50/bu= 3 bushels). With the addition of a fungicide application, costs increase by $24.00/ac (fusarium fungicide $14.00/ac + $10.00/ac application). To cover the cost of the fungicide, you would need an additional 4.3 bushels/ac ($24.00/$5.50) =4.3 bu).

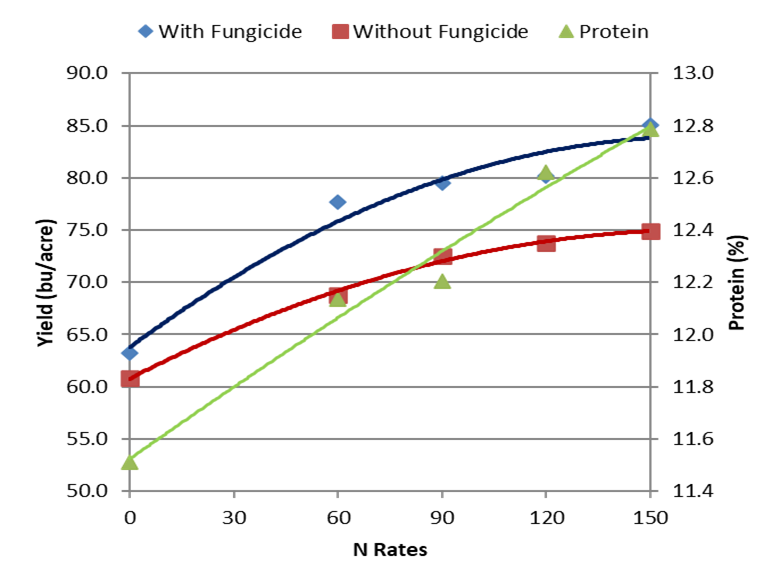

- Based on these assumptions and using the trend line from Figure 1: MER-N was reached with 91 N/ac with fungicide and only 70 N/ac without fungicide. However N response varied from year to year. Similar to winter wheat, MER-N rates are significantly higher with fungicide than without fungicide, for both years, indicating that a nitrogen x fungicide (NXF) synergy does exists. The nitrogen by fungicide synergy response means that the total response, when both treatments are applied, exceed the sum of the two individual responses. The MER-N values derived from these trials are significantly higher than currently recommended in the Agronomy Guide, Publication 811 (~90 lbs N/ac vs 63 lbs N/ac) when a fusarium fungicide is applied. This is likely due to improved genetics and N response with fungicide.

Figure 1: Southwestern Ontario Spring Wheat Nitrogen Response Curves

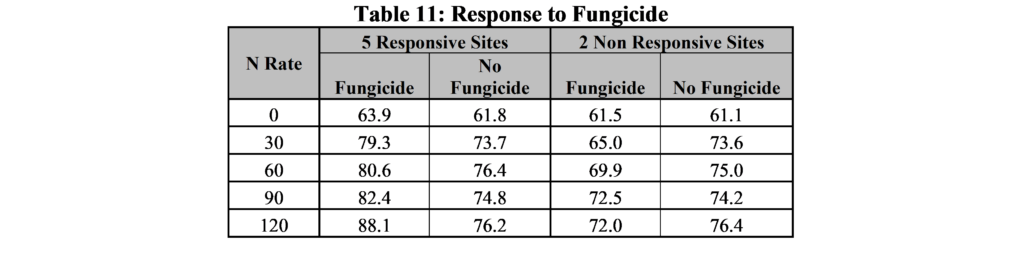

- On average, there was a significant and consistent yield increase to fungicide with high N rates in Southwestern Ontario. This is similar to winter wheat, where yields at zero N show little to no yield increase whether the fungicide is applied or not. As N rates increase, response with the fungicide applied increases dramatically. However, not every site showed this response. Five of the southwestern Ontario sites had a large response to fungicide, averaging ~10 bu/ac, while three had minimal response to fungicide. These results are shown in Table 11. On average, fungicide applications were economical: the sites where fungicide response was not economical tended to have lower yield potential. The non-responsive sites were all grown on sandy soils in regions that received low summer rainfall amounts. The lack of moisture would limit yield potential, which in turn limited the potential response to fungicide and N. For nitrogen management recommendations, soil water holding capacity may have to be a factor considered.

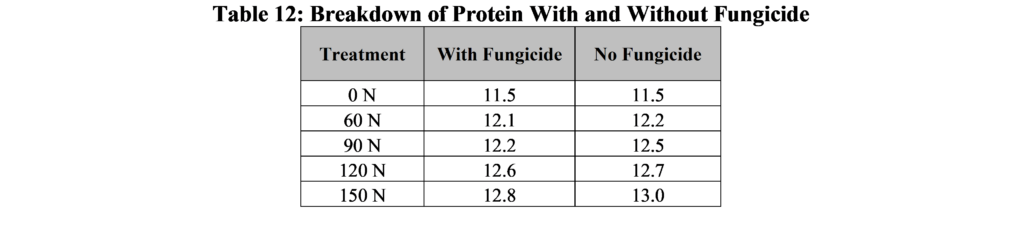

- The average protein results are summarized in Table 12. Protein response to nitrogen was extremely variable across locations making it hard to draw any conclusions. One site had very little change in protein across all treatments, due to significant residual soil N from a previous legume hay crop, while another site had a 2% increase in protein from 0 N to 150 N. In general, protein levels increased with additional N, which is the expected response. There was very little difference in protein content with or without fungicide at any given N level, but the trend was higher protein responses without fungicide than with fungicide. This is most likely reflective of the larger yield response in fungicide treated plots leading to more protein dilution.

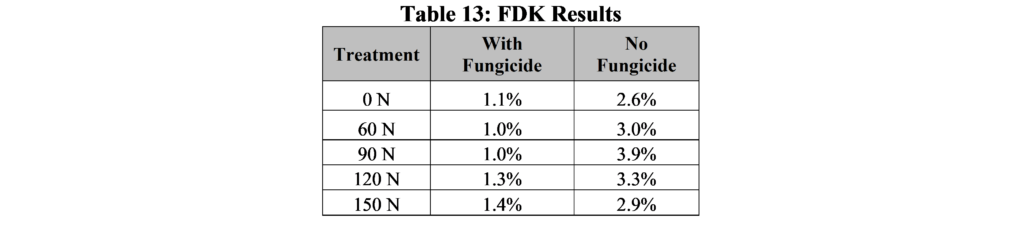

- The FDK results from a site near Owen Sound in 2014 are summarized in Table 13. Harvest was delayed due to wet weather until late September, which contributed to the high FDK counts. The results once again support the use of a Fusarium fungicide in spring wheat production. FDK counts were significantly lower where a Fusarium fungicide was used and made the difference between Grade 2/3 wheat and feed. In this case, the Fusarium fungicide resulted in increased return of over $100/acre. Only 2 of the 8 southern Ontario locations did not have a large enough yield increase to at least break even with a Fusarium fungicide application.

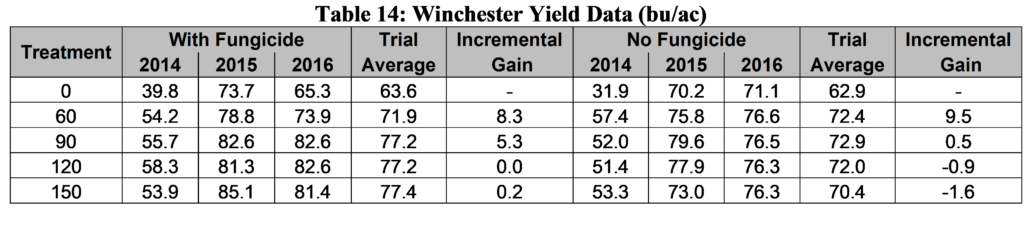

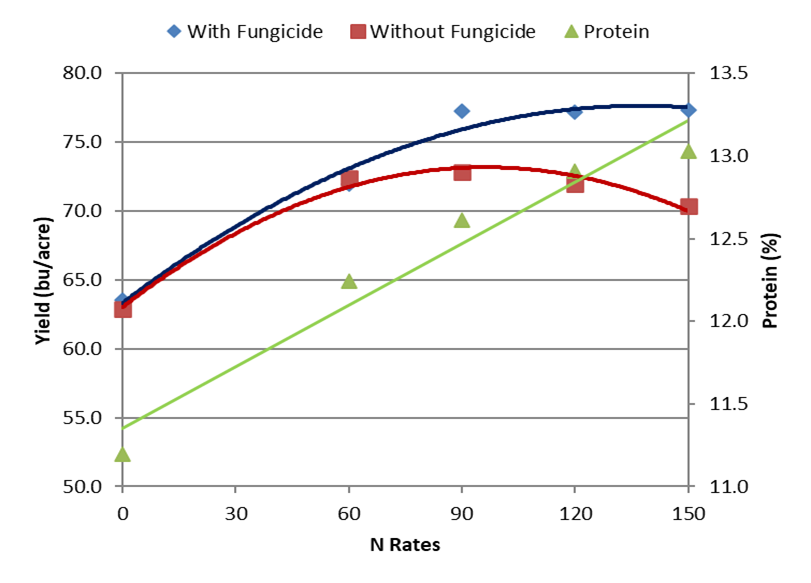

- The yield data from Winchester is shown in Table 14 while the N response curve is shown in Figure 2. There is little response to fungicide at Winchester with 60N, but yields remained consistent with high N rates when a fungicide is applied, while non fungicide treated yields dropped. This is primarily due to reduced lodging with the fungicide, and disease control in the lush canopies at high N rates. Based on this data and the assumptions listed above (spring wheat @$5.50/bu and N @$0.55/lb) MER-N was reached with 56 N when fungicide was applied and 57 N with no fungicide. Results were variable across locations with two sites having an MER-N of 0 N/ac. If these 2 sites are removed from the data, the MER-N was 65 N with fungicide and 62 N without. The MER-N values are slightly below the current recommends in the Agronomy Guide, Publication 811 (63 lbs N/ac). This data is consistent with the Winchester area (Area 3 in the Ontario Cereal Crop Committee Trials) being different and having more residual soil N than southwestern Ontario. However, site selection is also a factor: having 2 sites with an MER-N of 0 is quite unusual and reflects crop rotation with legume hay crops as well. Therefore, this data should be used carefully in the Area 3 region, with the potential for higher response to nitrogen a definite possibility. There was little difference in protein with or without fungicide, but protein levels increased in both cases with additional N as expected. The protein results are shown in Table 15.

Figure 2: Winchester Spring Wheat N Response Curve

Table 15: Winchester Protein With and Without Fungicide

| Treatment | With Fungicide | No Fungicide |

| 0 N | 11.2 | 11.3 |

| 60 N | 12.2 | 12.3 |

| 90 N | 12.6 | 12.5 |

| 120 N | 12.9 | 12.9 |

| 150 N | 13.0 | 13.1 |

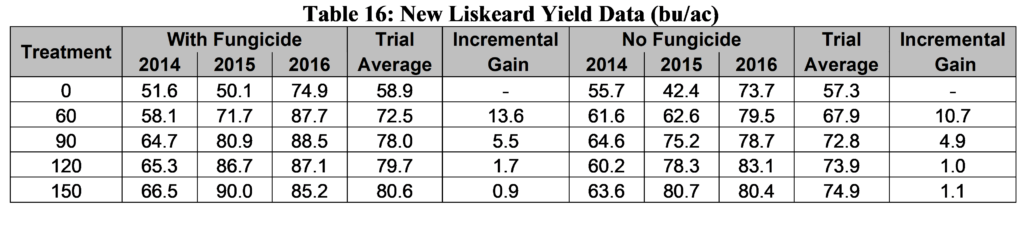

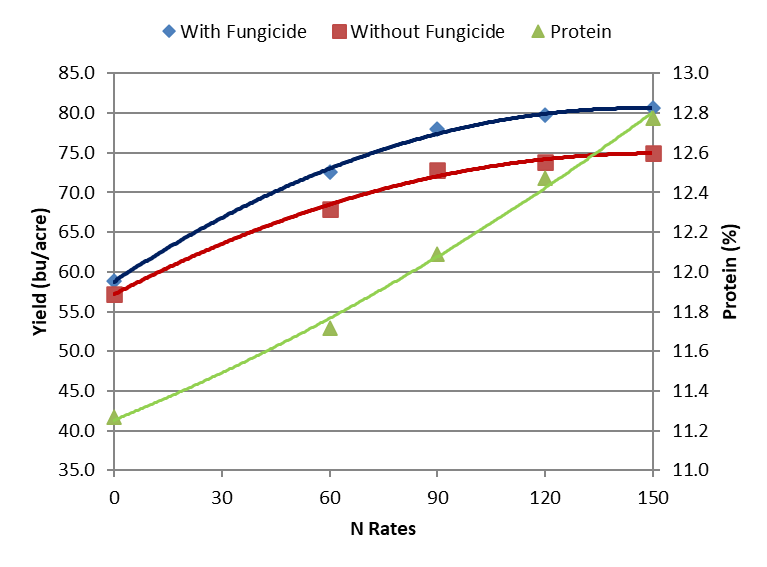

- The yield data from New Liskeard is shown in Table 16 while the N response curve is shown in Figure 3. This data is only based on one site over 3 years (3 site years), so these recommendations are made based on limited data. There does appear to be a NXF synergy as the gap between the fungicide and no fungicide curves begins to widen with high N rates. There is a strong response to added N at this location with MER-N occurring with 98 N when a fungicide is applied and 84 N without. The MER-N values are significantly higher than currently recommended in the Agronomy Guide, Publication 811 (63 lbs N/ac). This is based on very limited data: more research is required. There was little difference in protein with or without fungicide for each N rate (Table 17), with a trend at lower N applications towards slightly higher protein in non-fungicide treatments. This difference may be a result of larger yield increase with fungicides applied resulting in more protein dilution in the grain.

Figure 3: New Liskeard Spring Wheat N Response Curve

Table 17: New Liskeard Protein With and Without Fungicide

| Treatment | With Fungicide | No Fungicide |

| 0 N | 11.3 | 11.5 |

| 60 N | 11.7 | 12.1 |

| 90 N | 12.1 | 12.3 |

| 120 N | 12.5 | 12.6 |

| 150 N | 12.8 | 12.8 |

- A total of 21 winter wheat sites have been set up at 0, 60, 90, 120, and 150 N application rates with and without fungicide between 2014 and 2016. Data collected from these sites included yield, moisture, test weight, 1000 kernel weights, protein, disease ratings and lodging. Fusarium damaged kernel (FDK) counts were complete on sites with high Fusarium levels.

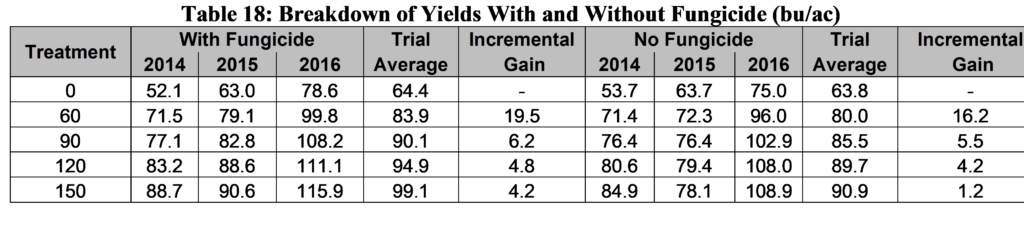

- Yields increased with the addition of N (Table 18). Yield increase was the greatest with the first addition of nitrogen, with subsequent increases being less with each addition of 30 lbs N. As indicated in previous research, zero N yields were essentially equal regardless of fungicide application. Yield increases are higher with fungicides applied than without fungicides for each additional increment of nitrogen (incremental gain). Additionally, without fungicides yield gains drop quickly above 90N, while yield gains with fungicides hold constant to 120N, and remain significant even to 150N. There was no impact of N rates on test weight, moisture or thousand kernel weights. Fungicide application did have a significant impact on thousand kernel weight.

- Using urea at $557/tonne ($0.55/lb of actual N) and soft red wheat at $5.00/bushel, 3 bushels of wheat are required to cover the cost of 30lbs of N ($0.55/lb*30lbs= $16.50/$5.00/bu= 3.3 bushels). With the addition of a fungicide application, costs increase by $24.00/ac (fusarium fungicide $14.00/ac + $10.00/ac application). To cover the cost of the fungicide, you would have to have an increase of 4.8 bushels ($24.00/$5.00) =4.8 bu). Using these assumptions, the 150 N with fungicide is the most profitable treatment on average (MER-N = 150 59% of the time). Using the trend line (Figure 4), the maximum economic rate of nitrogen (MER-N) occurs at 131 lbs N/ac with fungicide and 112 lbs N/ac without fungicide. Economic gains are small above 90 N without fungicides, and 120 N with fungicides. MER-N rates vary by location, thus full average MER-N rates are not necessarily recommended: MER-N represents the point of zero return to added N. Growers should do their own evaluation of N response above 90 N without fungicides and 120 N with fungicides. These outcomes will also be impacted by wheat price and nitrogen fertilizer price. On years with high wheat values, economic value to higher nitrogen applications (150 N) would increase. There appears to be little value to increasing N rates above 150 N/ac, with little yield benefit found with 180 N applied. This may evolve as wheat genetic yield potential improves, or other management strategies are found to support higher N applications and higher yields.

- The interaction of nitrogen and fungicides is interesting in this economic analysis. While 2014 and 2015 yields were lower than trend line due to harsh winter conditions and winterkill, the synergy between nitrogen and fungicide still existed. This indicates that even on crops with lower yield potential, management pays. It is critical to note that while the economic impact is small between 90, 120 and 150 N applications, at higher N rates the use of the fungicide becomes more profitable. Based on average data there was a 4.6 bu/acre yield increase from fungicide with 90 N. At 120N yield response increased to 5.2 bu/acre and 150N it increased further, to 8.2 bu/acre. This shows the importance of using fungicide and increased nitrogen rates together, to utilize this synergy, and gain increased value from both.

- The results from the 7 sites that contained a 180 N treatment are shown in Table 19. Yield increase is slight to the final 30-pound N increment. Although this is limited data (7 sites over 3 years), previous trials have also verified little response to 180N, or even a negative response when lodging occurred. Protein levels continue to increase with these higher N applications.

- Figure 4 contains the average protein results with and without fungicide. Protein slowly increased as nitrogen rate increased but there was no difference in response with and without fungicide.

Figure 4: Nitrogen and Protein Response Curves

External Funding Partners:

Growing Forward 2 (GF2)

This project was funded in part through Growing Forward 2 (GF2), a federal-provincial-territorial initiative. The Agricultural Adaptation Council assists in the delivery of GF2 in Ontario.

Project Related Publications:

None.